Automated weld overlay solution restores tower integrity

When a major industrial facility faced severe localized galvanic corrosion in multiple towers, threatening both operational safety and efficiency, they turned to Sulzer Chemtech Tower Field Services' Automated Weld Overlay (AWO) team for a comprehensive repair solution.

The Challenge

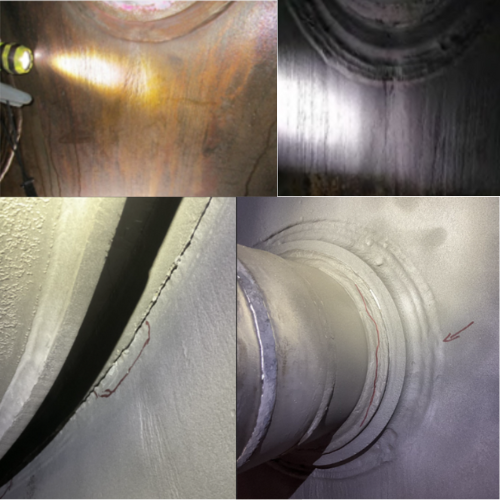

The corrosion mechanism was attacking critical areas just below the chimney tray in the scrubber towers, specifically at the transition zone from carbon steel with clad to pure carbon steel at a circumferential weld located at Elevation +8000 mm. This galvanic corrosion was causing significant sidewall thinning at various elevations, with the most affected section spanning from elevation +8000 mm down to +6650 mm. The problem was not isolated to a single vessel; identical corrosion patterns were identified across all three of the customer's towers, requiring a proven, reliable, and repeatable solution.

The AWO solution

Sulzer's Automated Weld Overlay division proposed a systematic two-stage repair approach. First, carbon steel build-up would restore the vessel wall to its nominal thickness. Then, a minimum 3 mm layer of Inconel 625: a highly corrosion-resistant alloy, would be overlaid to protect against future galvanic corrosion. This automated process ensures consistent quality, precise layer thickness, and superior metallurgical properties compared to manual welding techniques.

The comprehensive scope included complete removal of internals and attachments, thorough NDT inspection before hot works commenced, and the critical AWO application covering the entire affected zone from the chimney tray support down to support ring 3, including the internal wall of a manhole. Post-welding NDT verified the integrity of all repairs.

.png?width=500&height=500&name=VGPlus%20(1).png)

Execution excellence

Safety remained paramount throughout the project, with all work conducted under strict adherence to statutory health and safety regulations, Sulzer Chemtech's SCC and VCA Safety Systems, and site-specific protocols. An internal scaffold platform erected and positioned 500 mm below support ring 3, extending to the shell wall around the full circumference to provide safe access for welding operations. All surfaces underwent SA3-level sandblasting to ensure optimal weld adhesion.

Random packing was safely lifted using certified crane operations with lifting baskets, demonstrating the attention to detail applied across all aspects of the project. Beyond the welding scope, Sulzer's team executed extensive mechanical work on both the top and bottom beds, including demister housing modifications, installation of new random packing, and reinstallation of liquid distributors and hold-down grids.

Proven results

The successful completion of this repair not only restored structural integrity to the affected towers but established a proven methodology that could be replicated across all three vessels. The AWO technique delivered consistent, high-quality results while minimizing downtime and ensuring long-term corrosion protection.

This case demonstrates how Automated Weld Overlay technology provides an effective alternative to vessel or vessel segment replacement when facing localized corrosion in critical process equipment. The combination of advanced welding automation, corrosion-resistant materials, and comprehensive field services expertise enabled the customer to extend asset life while maintaining operational reliability and safety standards. Similar AWO solutions are applicable to a wide range of vessels including VDUs, CDUs, coker drums, Waste-to-Energy or biomass boilers, and other process equipment facing comparable corrosion challenges.

Have Questions or Need More Information?

We're here to help! Whether you have questions about our solutions or want to discuss how we can support your specific needs, feel free to reach out.