VersiSwirl CYPRES: overcoming the limits of gas-liquid separation

A new solution to address today’s industrial challenges

A step change in gas-liquid separation

The Shell VERSISWIRL* is a well-known, high-performance axial cyclone designed for efficient gas-liquid separation in industrial applications. During its development, it underwent extensive qualification in various industrially relevant systems. Over the years, it has proven its performance and robustness across a wide range of operating conditions in many industrial applications. Its strength stems from a combination of exceptional separation efficiency and a rugged design with a smart and effective mechanical implementation.

Industry challenges

Why innovate in preconditioners?

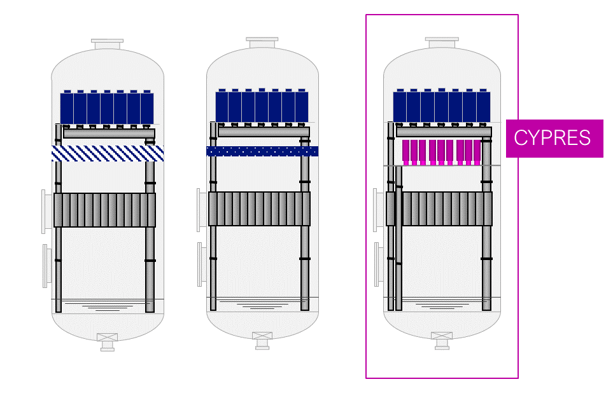

A key pillar of the VersiSwirl technology is the combination of the cyclone deck with an engineered preconditioner to maximize system efficiency.

The most well-known preconditioner is the Sulzer KnitMesh™ family of wire mesh. KnitMesh products are tailored to meet process requirements with a long history of boosting the performance of the VersiSwirl axial cyclone in many different applications.

These mesh-type preconditioners are usually operated above their flood point. In this operating condition, small droplets are captured and coalesced into larger droplets. This shift in droplet size distribution is a key mechanism for increasing the efficiency of the cyclone deck.

Some applications and fluids pose special challenges to the wire structure of such wire mesh preconditioners. These challenges include fouling and corrosion, which threaten the fine structure of these mist eliminators. Due to the high surface area, fouling is most likely to materialize in the fine structures of the wires and can lead to material buildup. In the worst-case scenario, the mesh can become completely plugged, ultimately resulting in the destruction of the preconditioner and complete loss of its droplet coalescing capability.

The industrially accepted solution for such fouling systems is the use of non-pocketed, vane-type mist eliminators from the Sulzer Mellachevron™ product range. Known for their robustness, Sulzer’s Mellachevron are an everpresent technology in separation applications. However, vane-type mist eliminators typically exhibit a significantly larger cut-off size than wire mesh preconditioner. This characteristic becomes even more pronounced at elevated pressures, where gas velocities, and thus inertial effects, decrease.

The industry faces production limitations due to increased liquid carry-over from aging fields and shifting production profiles, fouling and wax deposition that impair traditional preconditioners, more aggressive corrosion environments driven by complex gas compositions, and space constraints when upgrading existing operational plants.

The solution: VersiSwirl CYPRES

Shell Global Solutions and Sulzer Chemtech have now overcome the individual weaknesses above and introduced the new VersiSwirl CYPRES: a patented innovation designed to ensure superior coalescence and robustness.

The VersiSwirl CYPRES was developed to complement the VersiSwirl cyclone deck, addressing the individual weaknesses of wire mesh and vane packs as preconditioners. The innovative and patented design allows this new preconditioner to achieve superior coalescence and deliver a step change in overall efficiency and capacity. This performance boost across all applications comes with high robustness against fouling, allowing the use of VersiSwirl CYPRES in all applications where VersiSwirl Cyclone may be used.

These advantages make it possible to reduce separator size, optimize CAPEX and OPEX, and guarantee reliable performance under variable conditions.

Typical scrubber configurations with vane and wire mesh type preconditioner and the new VersiSwirl CYPRES.

The VersiSwirl CYPRES was developed and verified in different high-pressure systems to ensure the performance in industrial applications, enabling accurate sizing and performance predictions to provide customers with the most reliable performance. To achieve the highest overall performance, the VersiSwirl CYPRES is best combined with a Shell SCHOEPENTOETER* Plus Inlet device.

The VersiSwirl CYPRES is suitable for new builds or revamps and can be installed through manholes. It is available for all exotic materials where VersiSwirl is offered.

*Trademark owned and used by the companies of the Shell Group

Key facts

- Increased gas and liquid handling capacity up to 120%

- Reduced carry over by up to 80%

- Increased robustness towards fouling and mechanical upsets

- Installable through manhole

- Applicable for revamps or new builds

More Information: VersiSwirl

Have Questions or Need More Information?

We're here to help! Whether you have questions about our solutions or want to discuss how we can support your specific needs, feel free to reach out.

.jpg?width=352&name=shutterstock_1265388688%20(2).jpg)