Enzymes, crucial in industries from food production and textiles to pharmaceuticals and wastewater treatment, face challenges like limited shelf life, instability, and sensitivity to processing conditions. Immobilizing enzymes through encapsulation can overcome these limitations, improving their robustness and longevity.

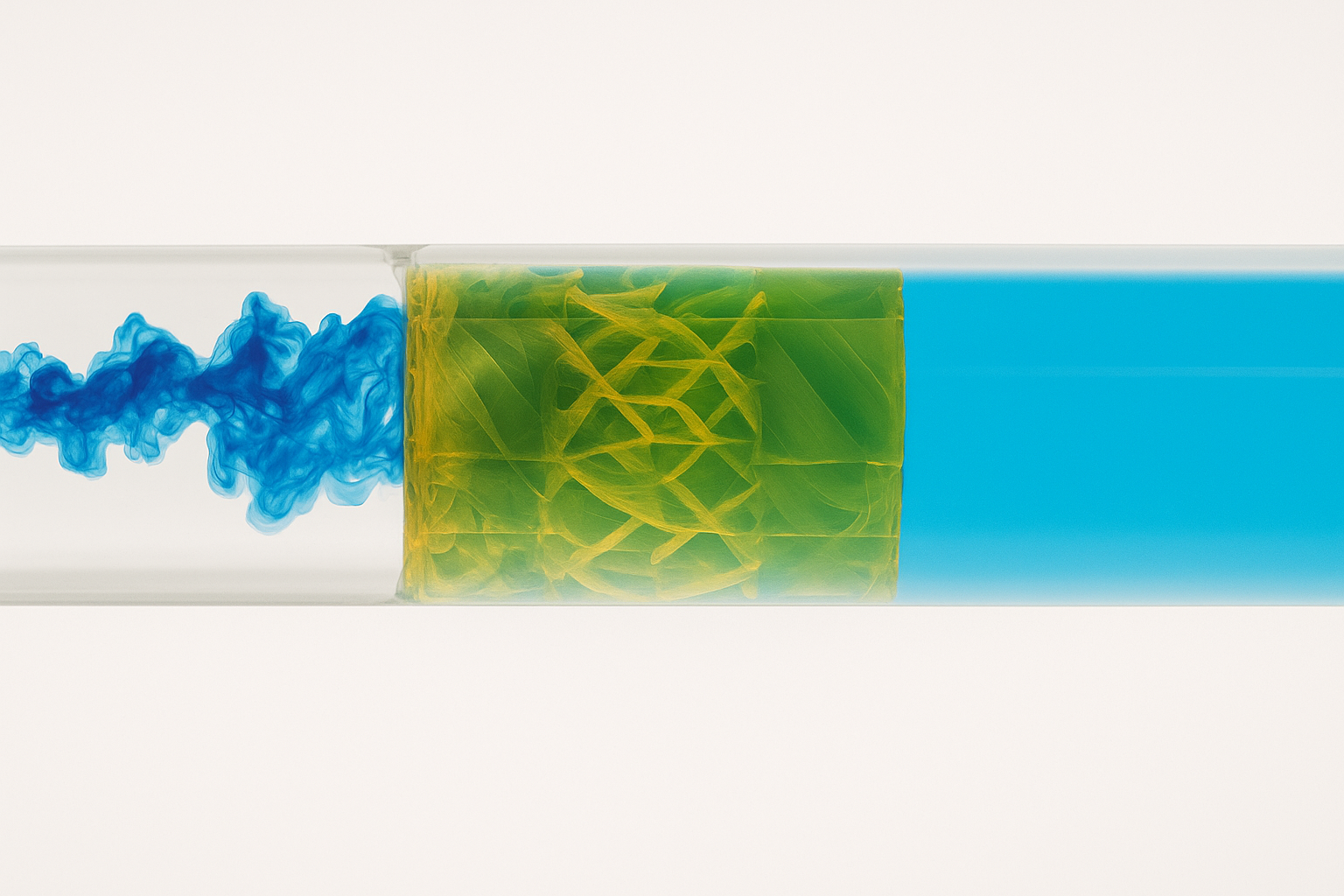

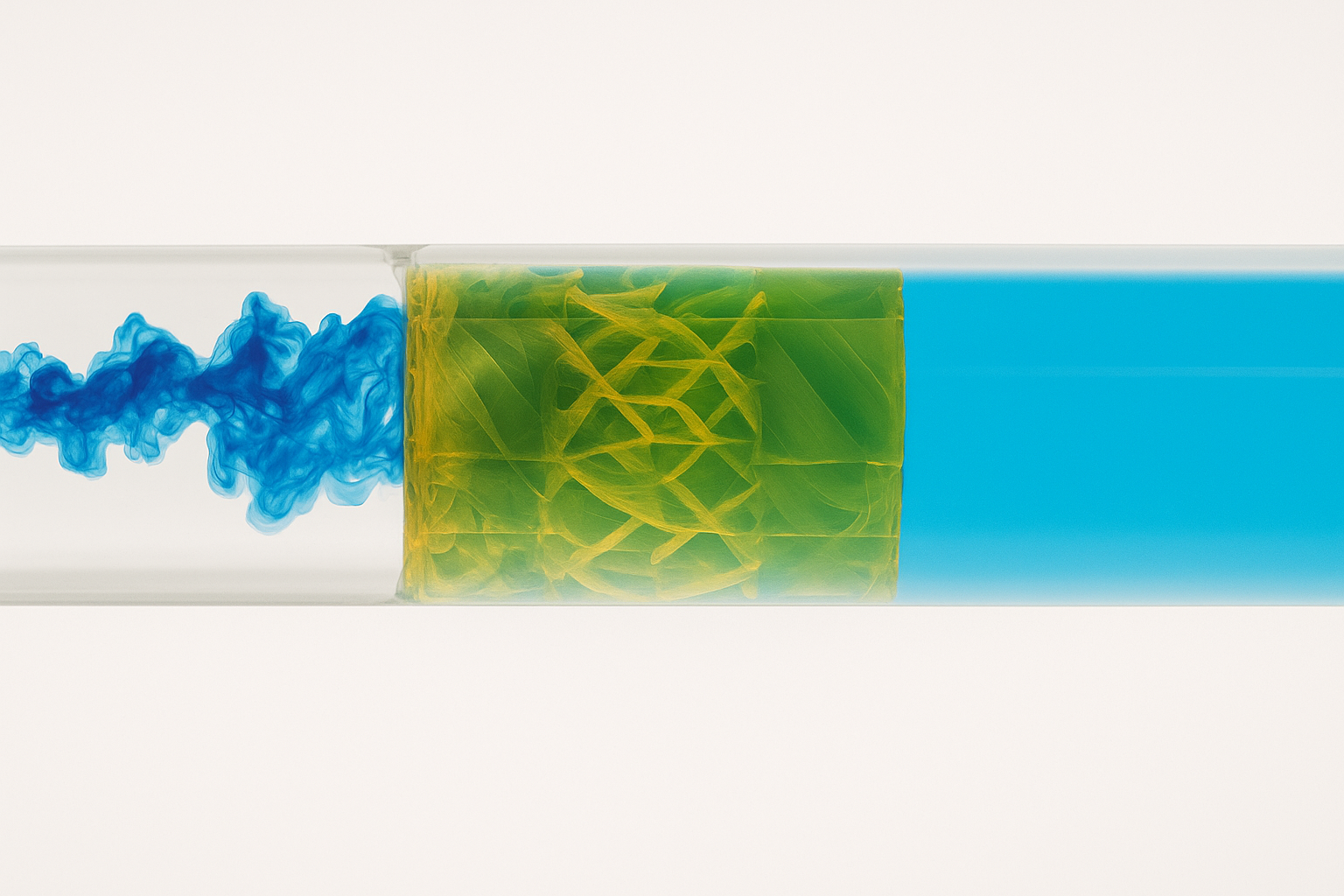

Traditionally, immobilization employs turbine stirred reactors; however, static mixers offer an innovative alternative. Utilizing for example K-Carrageenan—a marine algae-derived hydrogel—enzymes can be efficiently encapsulated through continuous emulsification. Unlike batch processes, static mixers significantly reduce emulsification times from 15 minutes to mere seconds, minimizing shear stress and preserving enzyme integrity.

Static mixers not only streamline enzyme immobilization but also deliver economic and operational advantages. They require only external pumping power, reducing both maintenance and operating costs. The gentle, uniform shear conditions ensure minimal enzyme damage and consistently produce smaller, highly uniform hydrogel beads with diameters as low as 19 µm—ideal for sensitive biochemical applications.

Furthermore, static mixers simplify scale-up processes, achieving consistent results from lab-scale to industrial production by merely adjusting tube diameters. This scalability, combined with easy maintenance—just flushing with water or solvent—greatly enhances productivity and reliability.

Safety and purity are paramount in enzyme applications, especially in food processing and pharmaceuticals. Static mixers' absence of moving parts significantly reduces mechanical failure risk, contamination, and potential hotspots, ensuring safer, cleaner, and more reliable processing environments.

Explore how Sulzer Chemtech’s static mixers are setting new standards in enzyme immobilization—driving innovation, efficiency, and sustainability in your industry.

Read our whitepaper “Enzyme Immobilization using Static Mixers” or reach out to us: mixers@sulzer.com