Sulzer VGPlus™ trays deliver 30% capacity boost in C3 splitter retrofit

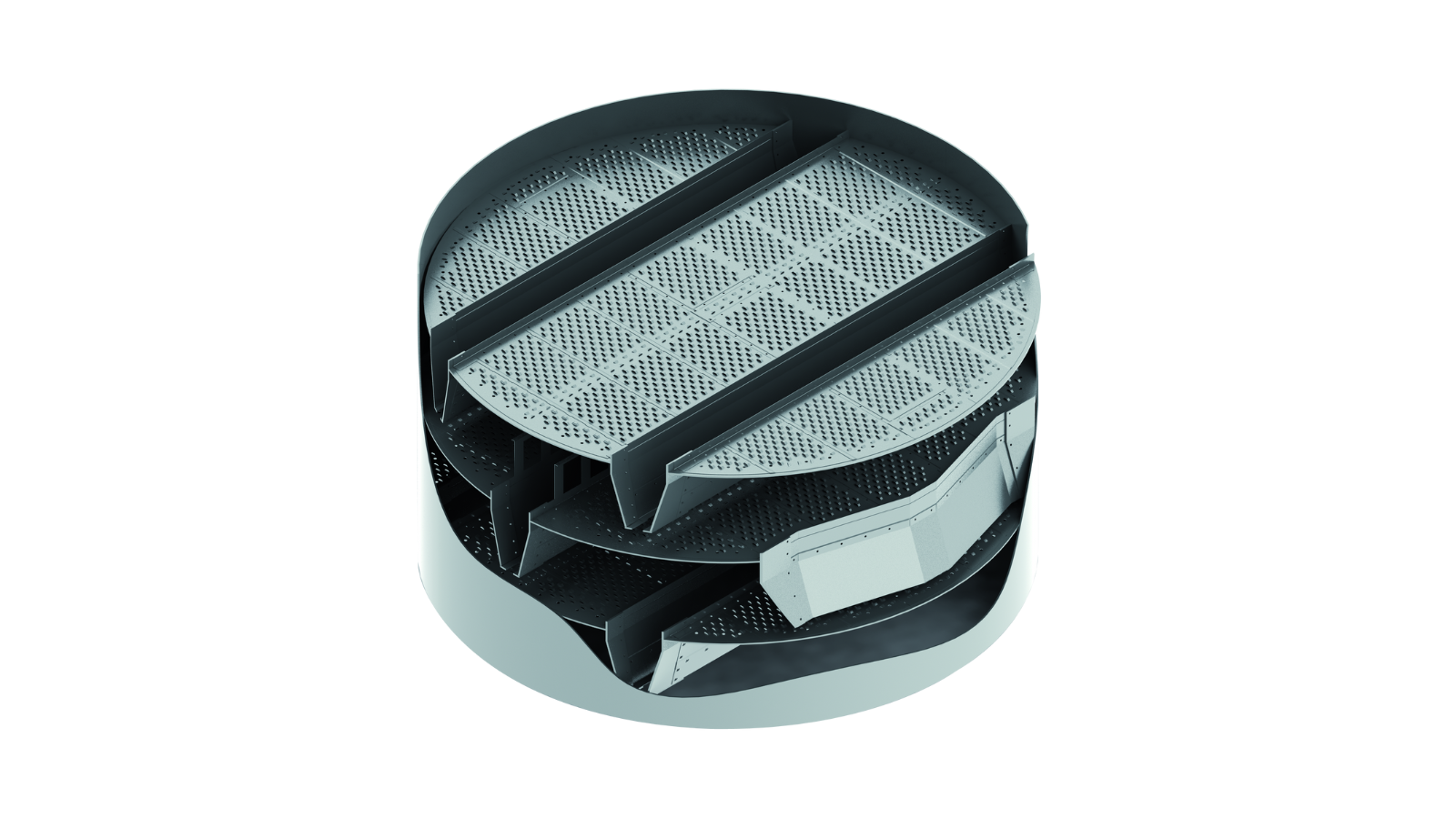

A recent retrofit project has demonstrated the substantial performance gains achievable in propylene-propane separation through advanced tray technology, by replacing conventional trays with Sulzer's VGPlus™ high-performance tray system, the facility achieved remarkable improvements in both product quality and operational efficiency, all completed in just 22 days.

Exceptional performance results

The retrofit delivered improvements across every key metric. Propylene purity increased from 99.34% to 99.77%, comfortably exceeding the design specification of 99.6%. Propylene losses plummeted from 2.0% to just 0.3%, well below the 1% specification and representing a significant reduction in valuable product loss.

The enhanced mass transfer efficiency of the VGPlus™ trays enabled a reduction in reflux flow rate by more than 10% , translating directly to energy savings. Meanwhile, pressure drop across the column decreased by 20%, further contributing to reduced energy consumption and improved hydraulic performance.

Efficiency gains beyond expectations

Perhaps most striking was the improvement in overall column efficiency. The retrofit nearly doubled efficiency from 50% to over 93%, substantially exceeding even the design case target of 81%. This efficiency gain, combined with favorable hydraulics, allowed the column to operate at 125% of its nameplate capacity, providing significant flexibility for future production increases.

Fast-Track installation

The entire retrofit was executed by Sulzer's Tower Field Services (TFS) team in just 22 days, minimizing downtime and production loss. This rapid turnaround demonstrates the value of experienced installation teams working with pre-engineered, modular tray designs.

The value of tailored design

This case study underscores the importance of customized tray design in separation applications. By carefully optimizing tray geometry, flow paths, and vapor-liquid contact mechanisms for the specific C3 splitter service, Sulzer's engineers delivered a solution that not only met but significantly exceeded performance expectations while ensuring reliable, long-term operation with reduced energy consumption.

Have Questions or Need More Information?

We're here to help! Whether you have questions about our solutions or want to discuss how we can support your specific needs, feel free to reach out.